Project support from instrAction

We support you in the development and design of your water treatment projects.

We offer comprehensive expertise in the removal of PFAS or heavy metals from industrial wastewater or drinking water in order to successfully implement your projects and plans in combination with our selective absorbers.

Phase 0 - Preparation

Questionnaire:

Information of the project / challenges

Expected kind of PFAS or heavy metals, concentration, volume, volume/time, origin of the solution, known and unknown by-products, targeted limits, site requirements

Availability of samples

Timeline of the project

Further processing like incineration or regeneration

Phase 1 - Analysis

Tasks:

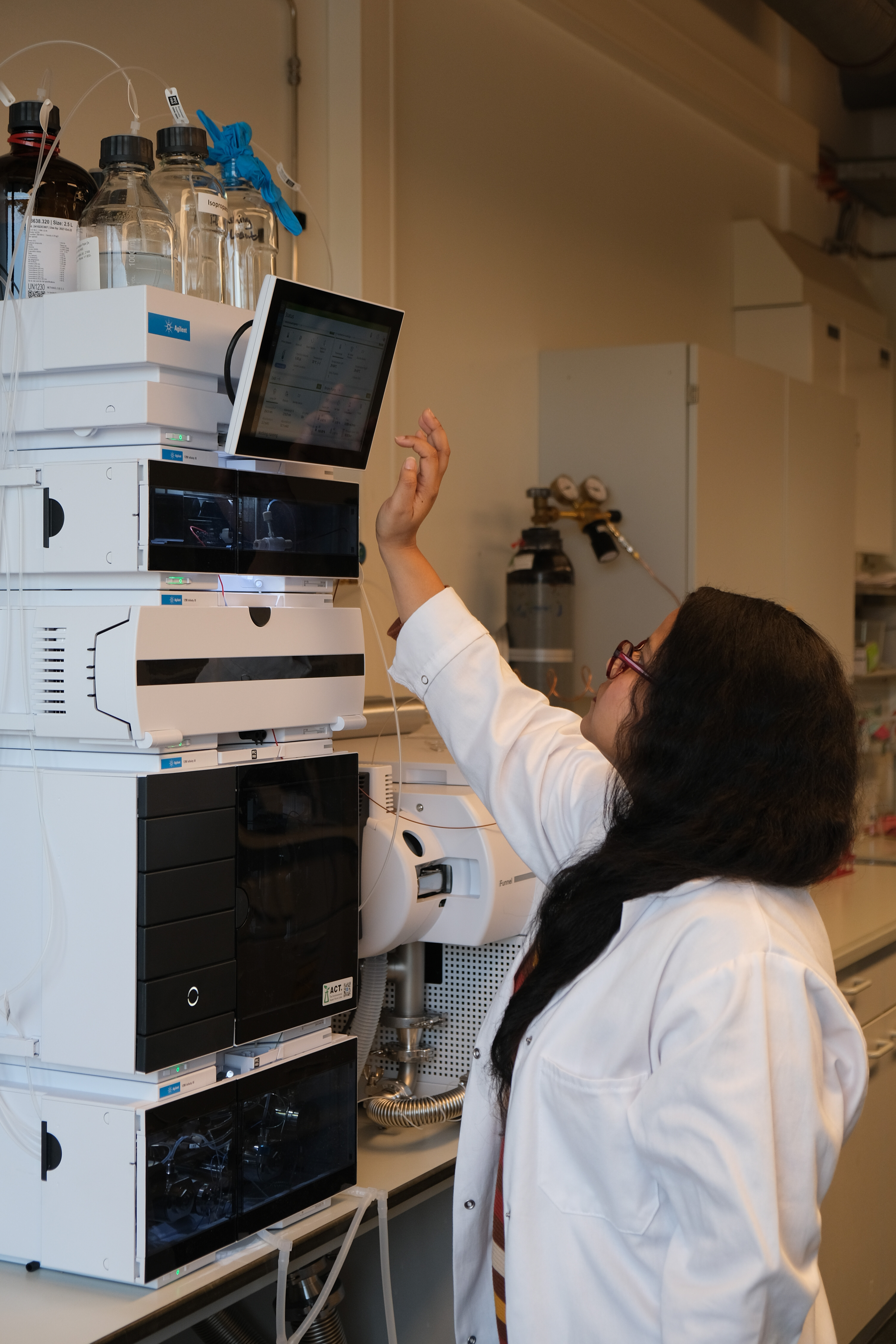

Quantitative analysis of 20 PFAS according to European guidelines with HPLC-MS/MS

Qualitative analysis of 149 PFAS possible with HPLC-MS/MS

Quantitative analysis of heavy metals and precious metals with ICP-OES or AAS

-----

Results:

Assessment of the ability to reduce/remove the compounds with instrAction resins.

The results will guide to the next steps, e.g. selection of resins etc.

-----

Scope of Delivery:

Formal analytical report

First project layout

-----

Timeline:

2 weeks

Phase 2 - Feasibility

Tasks:

Batch-absorption test (Isotherms)

Dependency of depletion on flow rate (productivity) is investigated

Break-through experiments

Fractions are taken twice a day, leading to ca. 50 samples (including blanks, feed etc.), which are analysed with

HPLC-MS/MS for the individual PFAS

ICP-OES or AAS for the individual metal

If regeneration is desired from customer site, a corresponding protocol will be developed and charged separately

-----

Results:

Individual depletion rates and a first capacity assessment for the different compounds in the solution

Estimation of lifetime

Assessment of required resin volumes, rough calculation of exchange frequency etc.

Necessity of pre-treatment like filtration or pH-adjustment

In the case regeneration is desired, a corresponding protocol is developed and tested, which may cause extra costs

-----

Scope of Delivery :

Written report and discussed in a meeting (online or on-site)

First process layout and calculation of potential resin costs.

-----

Timeline:

6-10 weeks

Phase 3 - Lab Pilot

Tasks:

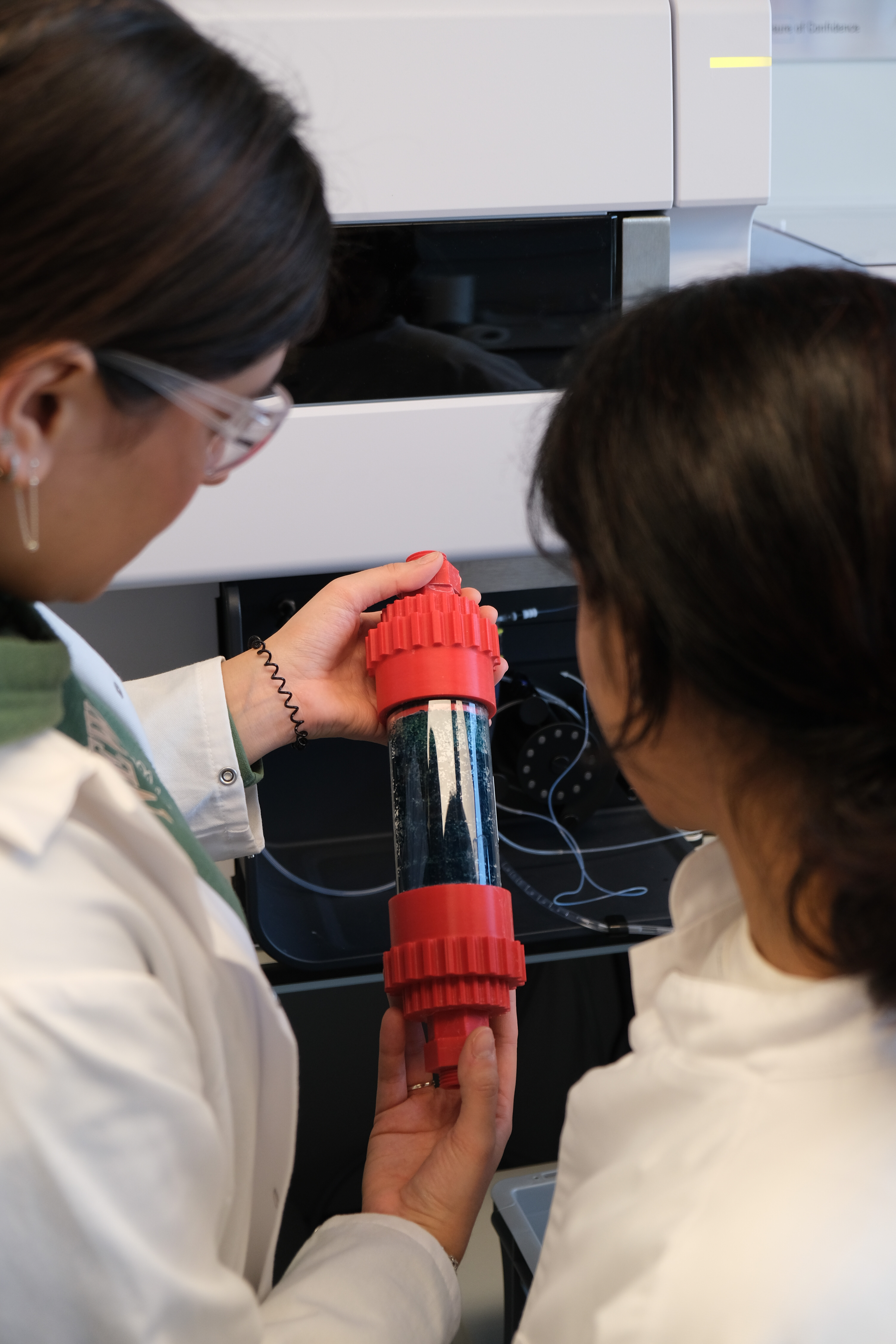

The most promising resin or resin motive will be used for pilot testing

Resin volume of 0,3 – 1 L

Scale-up tests, including flow rate variations, investigation of depletion rates, study of back-pressure behaviour

At instrAction, customer site or third-party site

Fractions (ca. 100) will be taken and analysed for

PFAS will be analysed with HPLC-MS/MS, heavy metals with ICP-OES or AAS

-----

Results:

Prove, that the system works like expected after feasibility study and a potential change in particle size.

Process parameters will be proven or adjusted.

Reliable, meaningful data are available, which allow a more precise calculation of the final process.

The application protocol is ready for further scale-up and transfer to customer.

-----

Scope of Delivery:

Written report or Manual

Instructions how to handle and implement the resin, including process parameters, detailed advice for use, calculation of final process

Detailed proposal for the method transfer and on-site pilot

-----

Timeline:

6-8 weeks

Our Team of Experts

Our team of passionate and highly motivated scientists is highly skilled in PFAS analysis, bringing over 60 years of combined experience and specialized knowledge to ensure the highest quality results. With a strong foundation in analytical chemistry and environmental science, our international team utilizes state-of-the-art technology and methodologies to detect and quantify PFAS compounds with precision. We are committed to providing accurate and reliable data to support your environmental and health safety needs, adhering to rigorous quality standards for trustworthy data and informed decision-making. We pride ourselves on our collaborative approach, working closely with clients to understand their unique challenges and provide tailored solutions for regulatory compliance, environmental monitoring, and health risk assessments.

Dr. Martin Welter

Chief Scientific Officer

University of Tübingen

PhD. in Chemistry

University of Würzburg

Master in Chemistry

Subhasri Tejaswini Vaddi

PFAS Project Manager

University of Duisburg-Essen

M.Sc. Water Science

GITAM University

B.Tech. Biotechnology

Fariha Bristy

Head of Analytics and Methodology

University of Duisburg-Essen

M.Sc. Water Science

University of Development Alternative

Bachelors in Pharmacy