We recycle

metals and precious metals

more effectively.

metals and precious metals

more effectively.

Recycling

of raw

materials.

Recycling of metals and precious metals from fluids up to 100% yield.

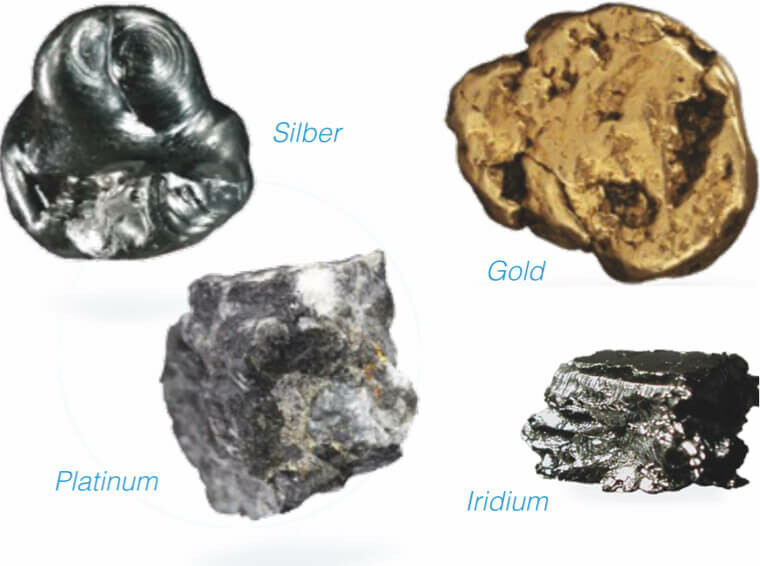

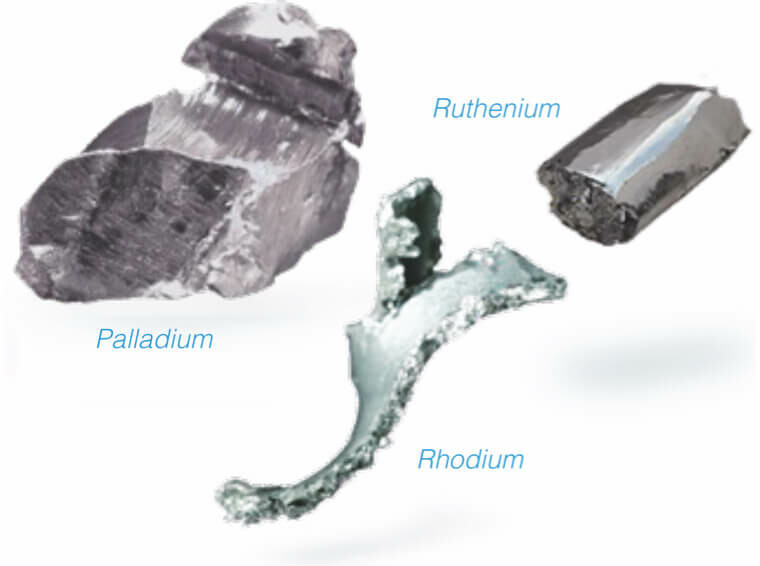

In light of dwindling resources, the recycling of raw materials is becoming increasingly important. Several metals in particular are enormously important for the industry due to their value (precious metals) or their availability (rare earths). Industrial process and wastewater streams contain considerable amounts of these metallic raw materials, worth billions of dollars. As the value of resources rises, recovery technologies are beginning to make sense for even parts-per-million traces of materials such as precious metals. Precious metals (Platinum, Palladium, Ruthenium, Rhodium, Iridium, Gold and Silver) are found in many wastewaters. These are often available in a form that is difficult to access for recovery.

With our deep scientific understanding, combined with the specialized instrAction absorbers, iA technology enables us to increase recovery yields of precious metals from industrial water streams up to 100%.

However, other metals such as copper or nickel can also be excellently filtered out of various wastewaters by using iA technology, so that the purified wastewater stream can be discharged into the wastewater network and does not have to be treated as hazardous waste.

Our Technology

Absorber resins with iA technology for metal recovery.

instrAction absorbers with iA technology bind even the smallest traces of precious metals or rare earths in aqueous or organic solvents and allow the recovery of valuable elements in an economical way. Combined with the deep scientific understanding und research capabilities recovery processes can be developed and executed to achieve highest possible yields.

Absorber resin for metal recovery.

instrAction resin for the recovery of metals, precious metals and rare earth from aqueous or organic solvents is a newly developed hydrogel absorber equipped with iA technology:

Selective removal of specific metals, precious metals and rare earth elements.

Outstanding capacity and productivity.

Silica-based resin, coated with a crosslinked Polyvinyl Amine, which forms its binding and

capturing sites.

High mechanical stability at low back pressure, can be used under high pressure conditions.

Broad applicability and chemical stability.

Use Cases for the metal and precious metal recovery.

Nickel containing wastewater is transformed from hazardous waste into a dischargeable water stream.

Until now, the nickel-contaminated process wastewater had to be declared as hazardous waste and disposed of accordingly, which is associated with high costs. Thanks to selective filtration, high productivity and loadability, the instrAction technology enables wastewater to be discharged into the public sewer system without any restrictions.

PGM (Platinum Group Metals) containing effluents from catalytic processes.

In the production of pharmaceutical products or agrochemical substances, homogeneous PGM catalysts are used, some of which are found in the wastewater stream. instrAction develops processes based on iA technology for an efficient recovery of the metals. In some cases, recycling rates of up to 100% are achieved.